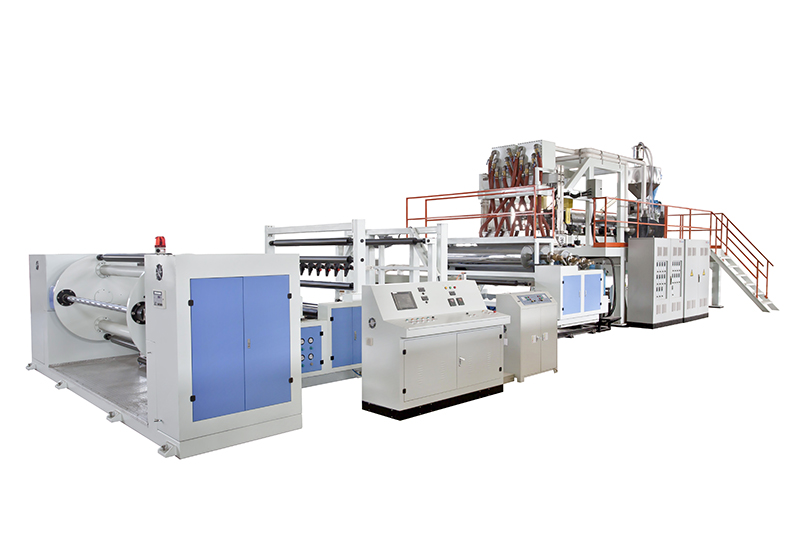

Cast Embossed Film Line, Hygiene Film Line

*SEKELETSO

Mohala oa filimi oa Cast o hlahisa lifilimi tse hatisitsoeng tse qhibilihisitsoeng bakeng sa lits'ebetso tsa bohloeki, tsa bongaka le tsa ho paka.Moralo o ntlafalitsoeng ka ho fetesisa oa extruder le T die o netefatsa ts'ebetso e phahameng ea ts'ebetso le maemo a fapaneng a likarolo le li-automation li teng ho fihlela litlhoko tsa hau hantle.

Extruder e fetola lipolymer hore e be resin e qhibilihang e tsoelang pele, ebe T die e e etsa joalo ka lesira la filimi.Ka sistimi e joalo ea extrusion ea filimi, moqolo oa tšepe o betliloeng le rabara ea silicon li kentsoe kariking ea mohala.Ha lesira la resin le qhibiliha le tsoa ho T die, le hatelloa holim'a moqolo oa embossing ka silicon roll ho hlahisa filimi e hatisitsoeng.Mekhoa ea ho khabisa filimi e ka etsoa ho latela lisampole tse teng kapa kopo ea bareki.Phetoho ea lipaterone tsa embossing e potlakile ebile e bonolo ka ho khutlisa lirolara tsa almanaka feela.Ka lebaka la ho khabisa holimo, ke lifilimi tsa tekheniki tse sebelisoang liindastering tse ngata.Wellson Machinery e na le boiphihlelo ba lilemo tse telele tsa ho etsa mehala ea lifilimi e kentsoeng bakeng sa bareki lefatšeng ka bophara.Theknoloji ea rona le tsebo ea rona li thusa bareki ba rona ho hlahisa lihlahisoa tsa bohlokoa bakeng sa limmaraka.

Mechini ea rona ea lifilimi e kentsoeng e sebetsa ebile e laoloa ke sistimi e tsoetseng pele ea PLC le sistimi ea HMI.Mechini ea rona ke motsoako oa tlhahiso ea lebelo le phahameng le tšebeliso e tlase ea matla ka lebaka la meralo e tsoetseng pele ea mochini.Ke tharollo e molemohali ea mochini bakeng sa baetsi ba lifilimi tsa tekheniki

*KOPO

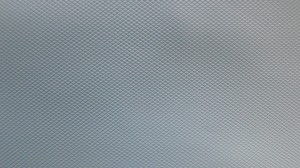

Melt embossing process e na le mefuta e mengata ea lits'ebetso, joalo ka filimi ea PE bakeng sa leleire la bana, napkin ea bohloeki, lihlahisoa tse sa tsitsang, pete ea lapeng, letlapa le lahloang, liaparo tsa bongaka, tse hōlileng, liatlana, sekoaelo sa lieta, filimi ea tokollo ea rabara, lesela la tafole, lesira la shaoara, joalo-joalo.

Melt embossed embossed filimi ea PE hangata e sebelisoa e le filimi ea bohloeki backsheet bakeng sa lesea leleire, sanitary napkin, leleire batho ba baholo, underpad.Re na le boiphihlelo bo boholo ho hlahiseng mochini oa lifilimi o kentsoeng ho fihlela litlhoko tse nepahetseng tsa ts'ebetso ea lifilimi tsa bohloeki le filimi ea PE bakeng sa lihlahisoa tsa bongaka tse lahliloeng joalo ka mese ea ho buoa, mese ea ho itšehla thajana.

*DITATI TSA BOTHEKELE

| Mohlala No. | Screw Dia. | E-shoa Bophara | Bophara ba Filimi | Botenya ba lifilimi | Lebelo la Mola |

| FME120-1600 | 120 limilimithara | 1900 limilimithara | 1600 limilimithara | 0.02-0.15mm | 200m/min |

| FME125-2000 | 125 limilimithara | 2300 limilimithara | 2000mm | 0.02-0.15mm | 200m/min |

| FME135-2500 | 135 limilimithara | 2800 limilimithara | 2500 limilimithara | 0.02-0.15mm | 200m/min |

Maikutlo: Mefuta e meng ea mechini e fumaneha ha u e kopa.

*DAKA LE MELEMO

1) Bophara ba filimi efe kapa efe (ho fihla ho 4000mm) ho sebelisoa ke moreki.

2) Ho bonolo ho fetola moqolo oa embossing bakeng sa lipaterone tse fapaneng tsa emboss.

3) Phapang e tlase haholo ea botenya ba filimi

4) In-line filimi moeling trim le recycled

5) In-line extrusion barbotage ke boikhethelo

6) Winder ea filimi e ikemetseng e nang le boholo bo fapaneng ba shaft ea moea